As the baseboard is close to a metre square I decided it would be best to include a beam across the middle to support the weight of the model or, at least, prevent the top of from bowing too much. This piece was simply a third side panel tacked and glued into place with wood glue and veneer pins.

I also used filler to solidify the corner joints of the baseboard, something I might find I will regret in the near future as it will get in the way of the feet I intend to put on the box. A rash decision, but hopefully easily rectified.

Baseboard without paved area attached

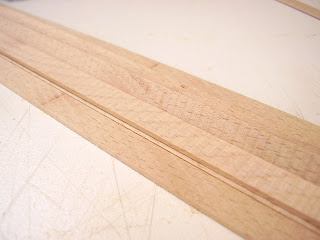

Underside of baseboard showing supportive beam